Why, wherefore and how do we develop how?

Several hours of development and dozens of trackday tests have gone into finding the perfect geometry for the wing feet, optimizing the connection to the boot lid and determining the right width for the wing blade.

SPEED Engineering GmbH

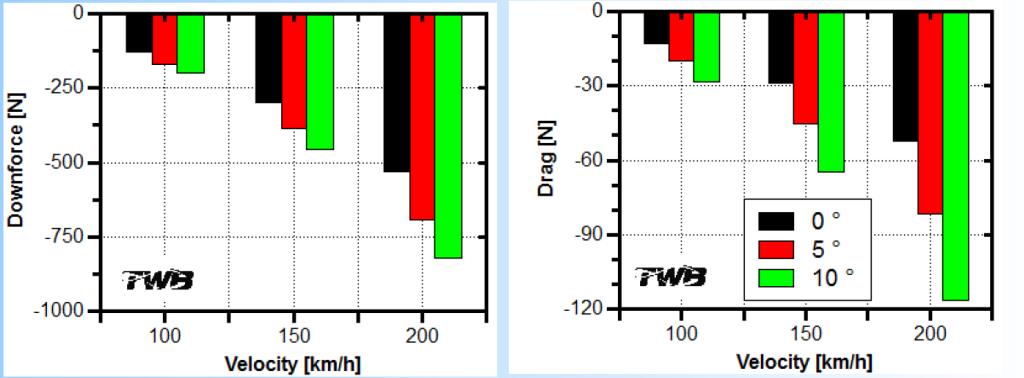

How doyou maximize the aerodynamically relevant surface area of a wing without significantly increasing drag (“driving resistance”) and breaking TÜV limits in the process? – Porsche is leading the way, we are following suit: With a drooping rear wing. Pure motorsport technology transferred to your track tools.

In the area where conventional, upright wing feet are bolted to the wing blade, turbulence forms due to the attachment, which results in a loss of downforce. This is because the main aerodynamically relevant surface of a rear wing is the underside and not, as is often assumed, the upper side! In order to compensate for this, the wing would have to be positioned significantly steeper into the wind. Negative effect: Significantly more drag. The car noticeably loses speed, while the probability of a stall also increases. You get unpredictable driving behavior, which is not particularly conducive to chasing the last tenths.

We have therefore taken the progressive route of designing a wing blade with maximum depth, which hangs suspended on your boot lid, follows the contours of the car and does not exceed the overall width of the passenger compartment or the A-pillars (an important feature for the TÜV!). Several hours of development and dozens of trackday tests have gone into finding the perfect geometry for the wing feet, optimizing the connection to the boot lid and determining the right width for the wing blade.

Customers came to us, described their experiences with other sashes, showed us weak points and gave us important wishes that were groundbreaking in the development of the mounting:

- It is important to find the right balance between rigidity and flexibility of the construction. A 100% rigid coupling of the components often redirects the resulting forces unfavorably, which was a difficult issue when adapting the wing to our Supra, for example. The realization: Even the best sash profile is useless without a fastening designed to withstand the forces.

- We have therefore taken the following approach for the M2 and BMW 2 Series: In order to transfer the downforce generated by the wing blade to your rear axle, we supply CNC-milled aluminum feet that are adapted to the radii of the trunk lid and integrate perfectly into the rear section. Carbon molded parts as counter plates inside the boot lid ensure that the resulting forces are dissipated over as large an area as possible and that the boot lid does not warp.

- We have also thought about the assembly. Save yourself the trouble of a ruined tailgate because you had to measure by hand and drilled “on the off chance”. Thanks to the cutting template and the aforementioned carbon molded parts from below, “poking around” from above with the drill is history.

-

Swan neck rear wing suitable for BMW 2XX M2 M2C F87 F22 with TÜV parts certificate

Swan neck rear wing suitable for BMW 2XX M2 M2C F87 F22 with TÜV parts certificateincl. 19% VAT

Lieferzeit: 3-4 working days

-

Swan Neck Wing rear wing Toyota Supra MK5 A90 with TÜV parts certificate

Swan Neck Wing rear wing Toyota Supra MK5 A90 with TÜV parts certificateincl. 19% VAT

Lieferzeit: 3-4 working days