Project: Customization for Artega GT CUP

Order:

Thermal optimization of the front axle brake system by means of air cooling. “It’s hard to believe that an official CUP vehicle from the factory doesn’t have brake cooling.”

Inventory:

Like its production counterpart, the Artega GT CUP used as a “race cab” has a 330 mm Brembo brake system on the front axle, which suffers from significant brake fading. This means that the vehicle loses braking power lap after lap and the driver has to adapt his braking behavior to this problem. The result: Increasing lap times and poor wear behavior of the brake system.

Development:

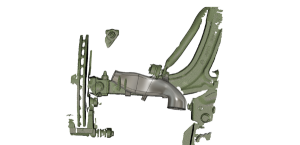

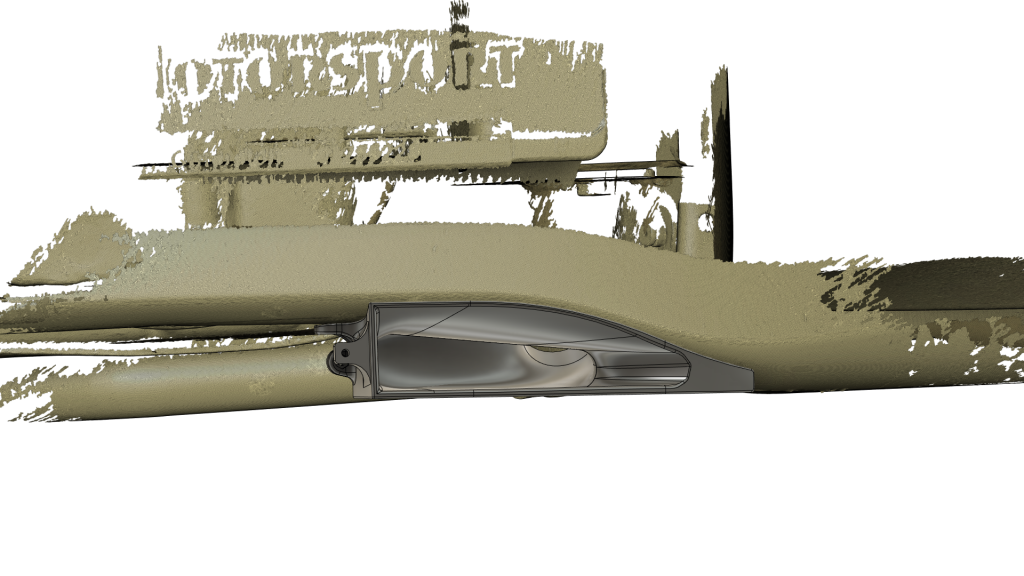

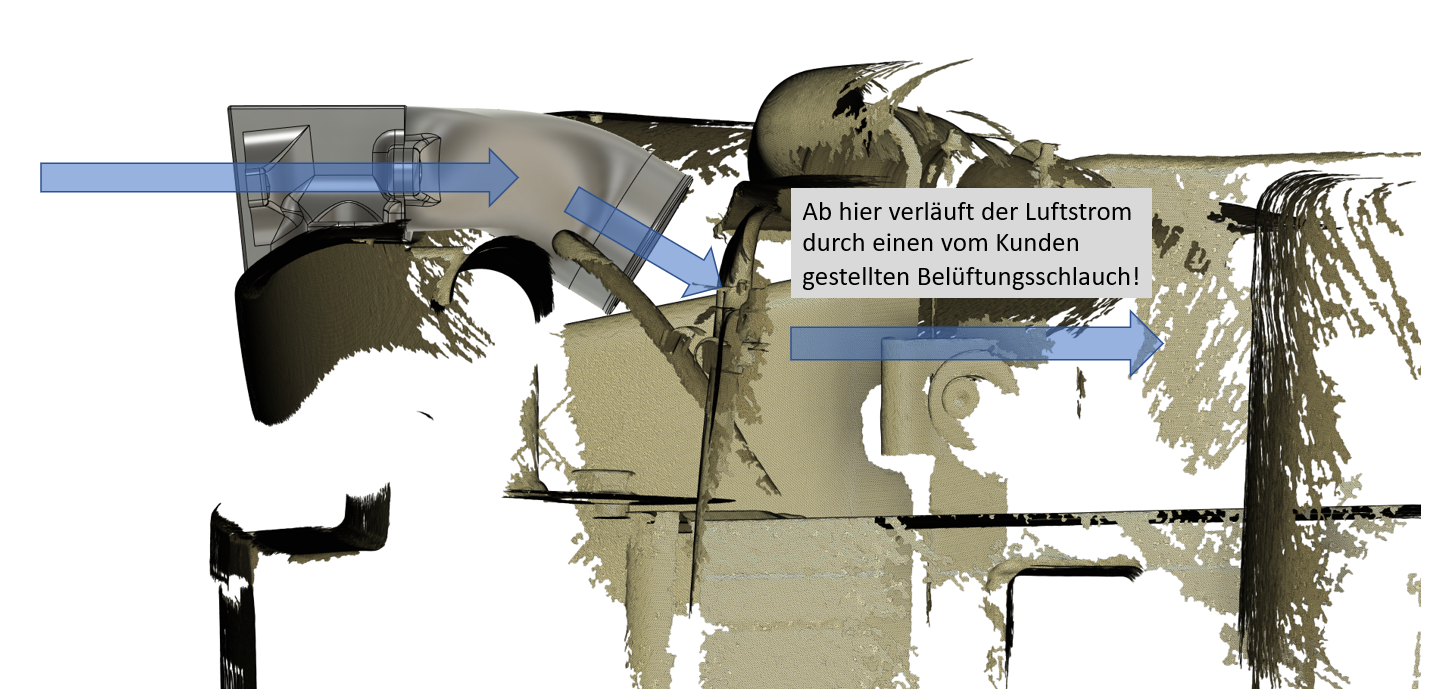

Funnel on the wishbone, hose on the existing anchor plate and “departure”? Our standards are higher for every vehicle, so that we have found a visually integrative solution for a vehicle of which there are only 8 in the world. The front apron of the Artega lends itself perfectly to taking up its shape and producing customized funnels using 3D printing. These have a hose connection to lead a ventilation hose to the anchor plate provided by the customer.

Nice gimmick?

The ground clearance remains unchanged, curbs can still be cleared and the front now offers a clean finish for fitting a splitter by the customer.

Conclusion:

About 100 °C temperature difference, between the left (equipped with our solution) and the right (uncooled) side, measured directly after a stint in the box!